2000 ford ranger wiring diagram manual

Category : Manuals

This section introduces the 2000 Ford Ranger Wiring Diagram Manual‚ essential for understanding electrical systems‚ troubleshooting‚ and repairs. It covers components‚ connections‚ and diagnostic procedures.

Use this guide to navigate wiring complexities‚ ensuring safe and effective maintenance of your vehicle.

1.1 Importance of Wiring Diagrams for Vehicle Maintenance

Wiring diagrams are vital for diagnosing and repairing electrical issues in the 2000 Ford Ranger. They provide a clear visual representation of the vehicle’s electrical circuits‚ helping technicians and DIYers identify connections and components.

These diagrams simplify troubleshooting by pinpointing fault locations and ensuring repairs are done safely and efficiently. Without them‚ even routine maintenance could lead to costly mistakes or unsafe conditions. Wiring diagrams are indispensable for understanding complex systems‚ making them a cornerstone of effective vehicle maintenance and upgrades.

1.2 Overview of the 2000 Ford Ranger Electrical System

The 2000 Ford Ranger’s electrical system is a complex network of wiring‚ circuits‚ and components that power essential functions. It includes the battery‚ alternator‚ fuse boxes‚ and various control modules. The system supports engine operation‚ lighting‚ accessories‚ and electronic features‚ ensuring reliable performance. Understanding this system is crucial for diagnosing issues‚ as it relies on precise connections and power distribution. Proper maintenance requires knowledge of how these components interact‚ making the wiring diagram an invaluable resource for technicians and enthusiasts alike. This guide provides detailed insights to help navigate the electrical layout effectively.

Electrical System Components

The 2000 Ford Ranger’s electrical system comprises essential components like the battery‚ alternator‚ fuse boxes‚ and wiring harnesses. These elements work together to power and control vehicle functions.

2.1 Battery and Alternator Wiring

The battery and alternator wiring in the 2000 Ford Ranger are crucial for the vehicle’s electrical system. The battery provides power when the engine is off‚ while the alternator charges it and supplies electricity to the vehicle’s components when the engine is running. Proper wiring ensures efficient energy distribution and prevents electrical failures. The wiring diagram manual details the connections‚ voltage regulators‚ and safety measures to maintain optimal functionality. Regular inspection and maintenance of these components are essential for reliable vehicle operation and longevity of the electrical system.

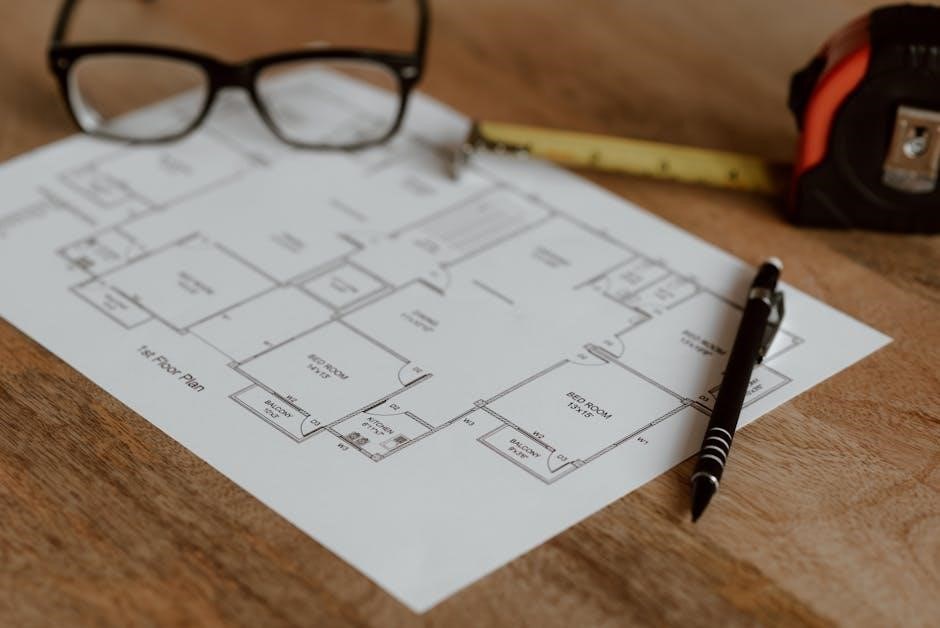

2.2 Fuse Box Diagram and Locations

The 2000 Ford Ranger features a fuse box diagram that outlines the location and function of each fuse. The primary fuse box is located on the driver’s side of the dashboard and under the hood. The diagram provides a detailed layout‚ identifying high-power fuses for components like the battery‚ alternator‚ and engine control systems. Additional fuses for accessories such as lighting‚ wipers‚ and horn are also mapped. Understanding the fuse box diagram is essential for diagnosing electrical issues and replacing fuses safely. Always consult the manual before attempting any repairs or modifications;

2.3 Power Distribution and Circuit Protection

The 2000 Ford Ranger’s electrical system relies on a robust power distribution network to ensure reliable operation of all components. The central junction box acts as the primary hub‚ distributing power to essential systems like the engine‚ transmission‚ and accessories. Circuit protection is critical‚ with fuses and relays safeguarding against overcurrent conditions. The wiring diagram details how power flows from the battery and alternator through the junction box to various circuits. Proper understanding of this system is vital for diagnosing faults and ensuring safe‚ efficient electrical performance. Always refer to the manual for precise locations and specifications.

Engine and Transmission Wiring

This section covers the wiring systems for the engine and transmission‚ including the ECM‚ TCM‚ and fuel injection. It details connections for sensors and actuators‚ ensuring proper communication between components for optimal performance. The wiring diagram provides a clear overview of circuit layouts‚ helping diagnose and repair issues efficiently.

3.1 Engine Control Module (ECM) Wiring

The Engine Control Module (ECM) is the brain of the engine‚ managing fuel injection‚ ignition timing‚ and emissions. This section details the wiring connections for the ECM‚ including input signals from sensors like the crankshaft position‚ camshaft position‚ and oxygen sensor. It also covers output circuits to components such as fuel injectors and ignition coils. Proper ECM wiring ensures accurate engine performance and diagnostics. The wiring diagram provides a clear layout of these connections‚ aiding in troubleshooting and repairs. Understanding ECM wiring is crucial for maintaining optimal engine operation and addressing faults effectively.

3.2 Transmission Control Module (TCM) Wiring

The Transmission Control Module (TCM) manages the automatic transmission system‚ ensuring smooth gear shifts and optimal performance. This section details the wiring connections for the TCM‚ including input signals from sensors like the transmission speed sensor and output circuits to components such as the solenoid pack. Proper TCM wiring is essential for accurate transmission control and diagnostics. The wiring diagram provides a clear layout of these connections‚ aiding in troubleshooting issues like erratic shifting or slipping. Understanding TCM wiring is crucial for maintaining transmission health and addressing faults effectively.

3.3 Fuel Injection System Wiring

The fuel injection system wiring in the 2000 Ford Ranger connects the Engine Control Module (ECM) to fuel injectors‚ sensors‚ and the fuel pump. The ECM processes data from sensors like the oxygen sensor and mass airflow sensor to control fuel delivery. Proper wiring ensures accurate fuel injection‚ optimizing performance and efficiency. Incorrect wiring can cause issues like poor engine performance or stalling. The wiring diagram details connections for the fuel injectors‚ fuel pump relay‚ and sensor circuits. Understanding this wiring is essential for diagnosing and repairing fuel system faults. Always refer to the manual for precise wiring layouts and troubleshooting guides.

Accessories and Electronic Features

This section covers wiring for accessories like radios‚ lighting systems‚ and wipers. It provides detailed diagrams for installing or repairing electronic features‚ ensuring proper functionality.

4.1 Radio and Entertainment System Wiring

The radio and entertainment system wiring section provides detailed diagrams for installing or troubleshooting audio components in the 2000 Ford Ranger. It covers connections for the radio unit‚ speakers‚ and amplifiers‚ ensuring proper sound output and functionality; This guide helps identify power wires‚ ground connections‚ and signal cables specific to the entertainment system. Whether upgrading or repairing‚ the wiring diagram offers a clear path to resolving issues or adding new features. Use this section to maintain or enhance your vehicle’s audio capabilities efficiently.

4.2 Lighting System Wiring (Headlights‚ Taillights‚ etc.)

The lighting system wiring section details the electrical connections for headlights‚ taillights‚ and auxiliary lights in the 2000 Ford Ranger. This guide provides diagrams to trace power sources‚ ground connections‚ and control circuits for proper illumination. It helps diagnose issues like dim or non-functioning lights and ensures safe operation. Use this section to repair or upgrade your vehicle’s lighting system‚ maintaining visibility and safety on the road. The wiring diagrams are essential for understanding how components interact and function within the lighting system.

4.3 Wipers and Horn Wiring

This section focuses on the wiring for the windshield wipers and horn system in the 2000 Ford Ranger. It provides detailed diagrams to identify electrical connections‚ control circuits‚ and power sources. Use this guide to diagnose issues like inoperative wipers or a non-functional horn. The wiring diagrams help trace connections between switches‚ motors‚ and fuses. Understanding this system ensures proper functionality for safety and convenience. Follow the manual to repair or upgrade these essential components effectively. The diagrams are crucial for troubleshooting and maintaining the integrity of your vehicle’s electrical systems.

Fuse Box Diagram and Specifications

This section provides detailed diagrams and specifications for the fuse box in the 2000 Ford Ranger. Locate fuses‚ understand their ratings‚ and identify circuits easily.

5.1 Fuse Box Location and Layout

The fuse box in the 2000 Ford Ranger is located under the driver’s side dashboard. It contains relays and fuses for various electrical systems. The layout is divided into compartments‚ with labels indicating each fuse’s function. A diagram in the manual helps identify the location of each component‚ ensuring easy access for diagnostics and repairs. This compartmentalized design simplifies troubleshooting and reduces the risk of electrical system damage. Always refer to the diagram for accurate fuse identification.

5.2 Fuse Ratings and Functions

The 2000 Ford Ranger Wiring Diagram Manual provides detailed information on fuse ratings and their respective functions. Each fuse is assigned a specific amperage rating‚ ensuring proper circuit protection. For example‚ a 10-amp fuse might control the radio‚ while a 20-amp fuse could power the windshield wipers. Understanding these ratings is crucial for diagnosing electrical issues and replacing fuses correctly.

Always refer to the manual to identify the correct fuse for each system. This ensures safe and efficient repairs‚ preventing potential damage to electrical components. The manual’s clarity simplifies troubleshooting and maintenance tasks.

Maintenance and Troubleshooting

This section provides guidance on maintaining and diagnosing electrical issues in the 2000 Ford Ranger. Regular inspections and troubleshooting techniques are covered to ensure optimal functionality.

Learn how to identify common problems and apply effective solutions using the wiring diagram manual as a reference‚ ensuring your vehicle runs smoothly and efficiently.

6.1 Common Electrical Issues and Solutions

Common electrical issues in the 2000 Ford Ranger include blown fuses‚ faulty sensors‚ and wiring harness damage. Blown fuses can often be resolved by identifying and replacing the faulty circuit.

Corrosion in connectors or wiring can cause intermittent problems‚ requiring thorough cleaning or replacement. Faulty sensors‚ such as oxygen or crankshaft sensors‚ may trigger warning lights and require diagnostic testing.

Consult the wiring diagram to trace and repair damaged wires‚ ensuring proper connections and power distribution. Regular inspections can prevent many electrical issues‚ keeping your vehicle running smoothly and reliably.

6.2 Tools and Equipment for Wiring Repairs

For wiring repairs on the 2000 Ford Ranger‚ essential tools include a multimeter for diagnosing electrical issues and wire strippers for preparing connections.

A set of pliers‚ screwdrivers‚ and crimpers is necessary for handling wires and connectors. A circuit tester can help identify live wires‚ ensuring safety during repairs.

Thermal tape or shrink tubing is recommended for insulating connections‚ while a wiring diagram provides a clear guide for tracing circuits.

Additional items like a fuse puller and a soldering iron may be needed for more complex fixes. Proper tools ensure accurate and efficient wiring repairs.

Resources and References

OEM manuals‚ online forums‚ and repair guides provide detailed wiring information. Websites offer downloadable diagrams‚ while automotive communities share troubleshooting tips and solutions for the 2000 Ford Ranger.

7.1 OEM Manuals and Guides

OEM manuals provide authentic and detailed wiring diagrams for the 2000 Ford Ranger. These guides include full wiring schematics‚ component locations‚ and connector details. They are designed for dealership mechanics but are invaluable for DIY repairs. The OEM manual covers bumper-to-bumper wiring‚ ensuring comprehensive understanding. It features over 400 pages with images‚ detailing every electrical aspect. This resource is essential for accurate troubleshooting and repairs‚ ensuring reliability and safety. By following OEM guidelines‚ users can maintain their vehicle efficiently and effectively‚ adhering to manufacturer standards.

7.2 Online Forums and Communities

Online forums and communities are invaluable resources for wiring diagram-related queries. Websites like Ford Ranger forums and Reddit groups offer extensive discussions‚ user-generated wiring diagrams‚ and troubleshooting tips. Members share real-life experiences‚ DIY repairs‚ and solutions to common electrical issues. These platforms often include downloadable resources and guides‚ providing accessible alternatives to official manuals. While not substitutes for OEM materials‚ they offer practical insights and community support. Engaging with these forums can help resolve specific wiring challenges and connect you with experienced enthusiasts and mechanics who understand the 2000 Ford Ranger’s electrical system.